Papercrete homes offer affordability

December

1, 2001

|

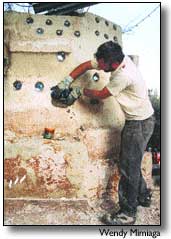

| PHILIP

MIRKIN works on an addition to his papercrete home in Egnar recently.

Mirkin, who offers seminars on building homes with the alternative

method, says it is cheap, safe and easy for do-it-yourselfers. |

By

Jim Mimiaga

Journal Staff Writer

Need

to build a quality home fast and on the cheap?

Check

out an alternative building technique that combines newspaper or clay

with cement to form sturdy bricks and walls that stand up to strength

tests.

Using

either the "papercrete" or "fibred-adobe" process,

a modest 1,000 square-foot home could be built in only a few months with

$2,000 in materials, according to Philip Mirkin, an architect from Egnar

who teaches seminars on the process.

Mirkin,

40, fell in love with papercrete because of its creative possibilities

and affordability.

"It

is easy to do and dirt cheap," says Mirkin. "Ten-year-old kids

are strong enough to build a papercrete house -- it's that simple."

In

contrast, wood-frame homes typically cost between $20 and $30 per square

foot, as do straw-bale homes. Both types of construction also require

ample expertise.

The

recipe for making papercrete bricks calls for one part clay or newspaper

(or both), one part water and one part Portland cement. Combine; pour

pulp into desired forms; allow to dry. The resulting papercrete or fibredobe

brick is so strong, it exceeds the tensile strength of cement and has

proven load-bearing capacity.

"The

paper fibers lock in with the clay or cement and create a matrix of interwoven

material that's lightweight and very strong," Mirkin said, adding

that the building material will hold up for 150 years.

To

mix large quantities, Mirkin uses an innovative contraption. He fitted

a truck bed with a large container that, at the bottom, has a lawnmower

blade connected to the truck's drive train. Once the ingredients are added

to the 200-gallon mixer, the truck is driven around a bit and, presto!

-- a thick mud suitable for construction is formed.

Once

the bricks or shaped forms have dried out, which takes between one and

three weeks, they are ready to be stacked to form walls, arches, doorways

and roofs.

The

same mud is used for mortar and as a plaster after the wall is up. The

structure can then be sealed with linseed oil or paint.

The

result is an adobe-style house, but without the high cost. Advocates say

papercrete has advantages over straw-bale construction because the papercrete

walls are load-bearing, more versatile and less labor-intensive.

Other

attributes are that it is fire-proof, does not use toxic materials, encourages

conservation and recycling, saves trees and has a high insulation value.

Because it is so light, building with papercrete does not require a foundation.

Wet weather does not harm the material, and roofs can hold up to 20 feet

of snow.

The

method has been around since the 1920s but is just now gaining significant

acceptance. Mirkin expects papercrete to become as mainstream as strawbale

construction, and says the federal government is about to approve it as

code-worthy.

The

town of Crestone, Colo. has adopted the technique as an acceptable alternative

that meets building codes. There are some 20 papercrete homes in Crestone.

Curved

walls and dome ceilings are easily built using the material, Mirkin said.

He is experimenting with red willow woven into the ceiling as a natural

highlight.

And,

amazingly, a wall built with this material has such strength that windows

can be cut in by using a chainsaw, Mirkin explained.

"It

is very free-form, so say you want a window shaped as a half-moon, then

get out the chain or jig-saw and cut away," he said. "It's almost

impossible to screw up using this material."

Mirkin

is offering several seminars this winter.

One

is today from 11 a.m. to 4:30 p.m. at Mirkin's place near Egnar. A workshop

follows on Sunday, Dec. 2, beginning at 11:30 a.m. Cost is $35 for the

seminar and $20 for the workshop.

Two

others will be held in Durango on Dec. 8 and 9. That one costs $50 total.

Call 677-3600 to register and for directions. Space is limited.

Mirkin

can also be reached via e-mail at

Copyright

© 2001 the Cortez Journal. All rights reserved. This article reproduced

here under the fair use guidelines as codified in Section 107 of the Copyright

Act of 1976.

The original form of this article appeared in the Cortez

Journal Online.

|